BROOKS 4800 Series Elastomer Sealed Thermal Mass Flow Controllers & Meters

Ultra-fast response for time-critical flow processes.

Description

Ultra-fast response for time-critical flow processes.

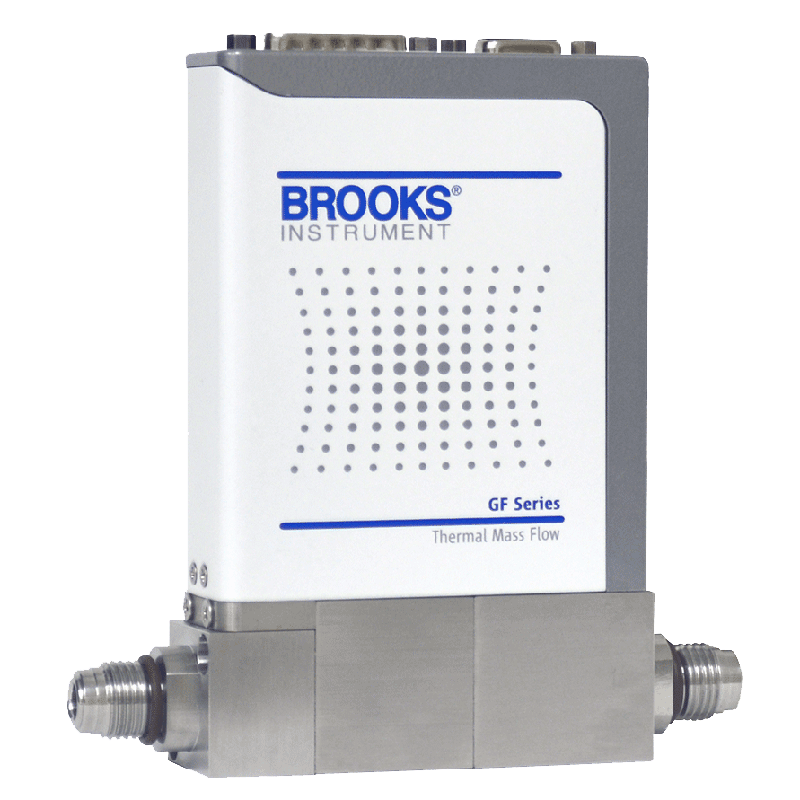

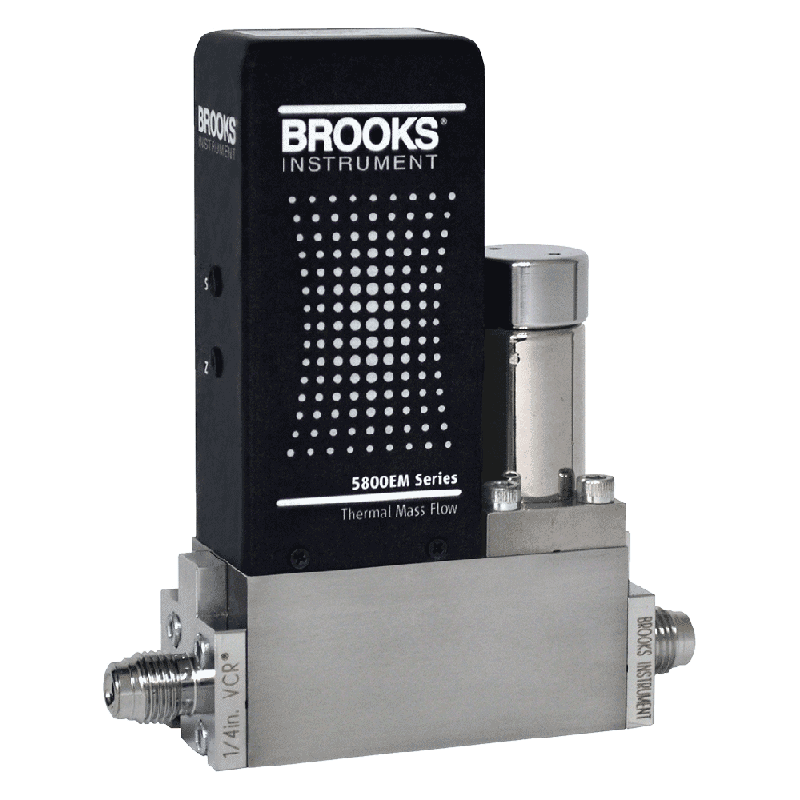

Models 4850 / 4860

| 4850 | 4860 | |

| Product Type | Mass Flow Controller | Mass Flow Meter |

| Flow Range (Full Scale Capacity) | 50 sccm-40 slpm | 50 sccm-40 slpm |

| Accuracy |

3.0% F.S.

1.0% F.S.(optional)

|

3.0% F.S.

1.0% F.S.(optional)

|

| Repeatability | 0.15% F.S. | 0.15% F.S. |

| Response Time | Normally Closed Valve: 300 ms-<1 sec | Normally Closed Valve: 300 ms-<1 sec |

| Max Pressure | 150 psig/10 barg | 150 psig/10 barg |

| Diagnostic Capability |

Status Lights: MFC Health, Network Status

Alarms: Sensor Output, Control Walve Output, Over Temperature,Power Surge/Sag, Network Interruption

Diagnostic/Service Port: RS485 via 2.5 mm jack

|

Status Lights: MFC Health, Network Status

Alarms: Sensor Output, Control Walve Output, Over Temperature,Power Surge/Sag, Network Interruption

Diagnostic/Service Port: RS485 via 2.5 mm jack

|

| Analog Communication |

0-5 Vdc

4-20 mA

|

0-5 Vdc

4-20 mA

|

| Digital Communication | RS232 | RS232 |

Features:

- Flow response time (settling time) of less than 0.75 seconds

- Innovative MEMS sensor and proprietary PID algorithm

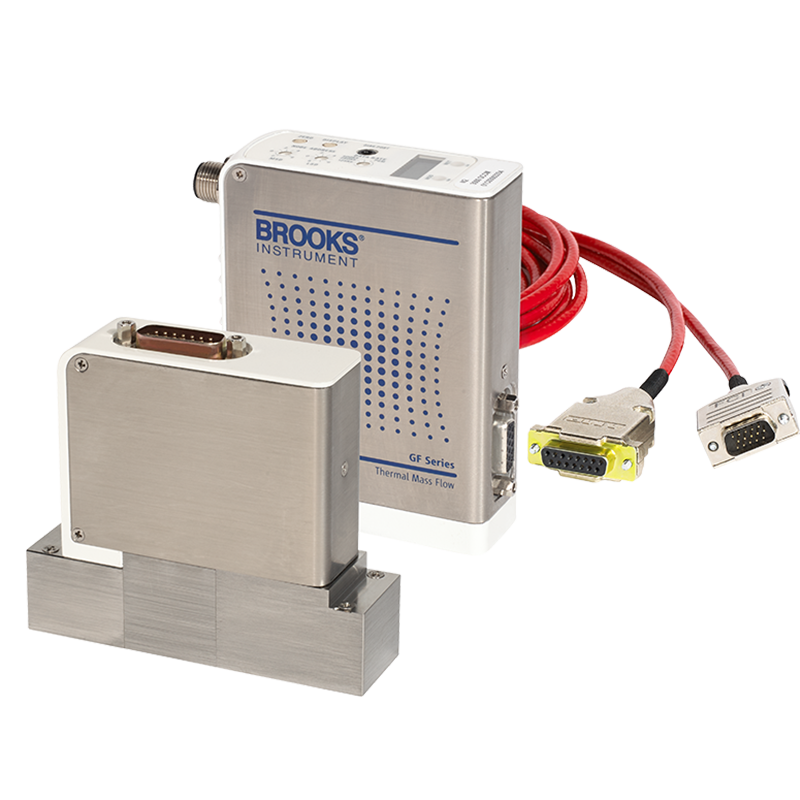

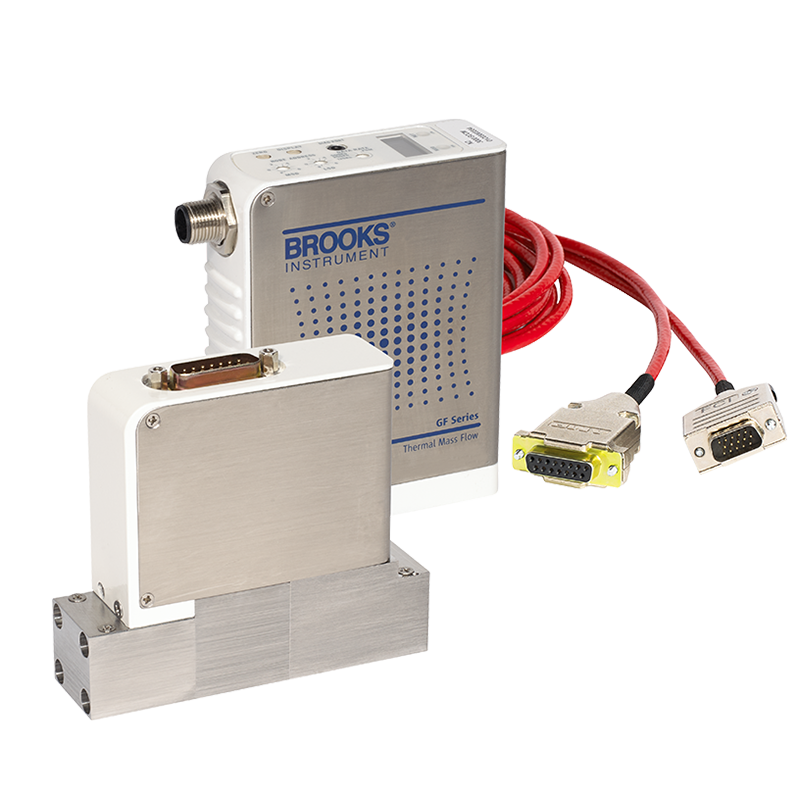

- Compact size, less than half the size of typical thermal MFCs: 1″ x 3″ x 4″ (25 mm x 76 mm x 101 mm)

- Optional Local Operator Interface (LOI) simplifies set-up and operation, with a free LabVIEW VI download for monitoring and zeroing the device

- Digital capability via RS-232

Benefits:

- Well suited for a wide range of common, non-corrosive gases

- Fast response time ensures rapid steps during process recipe changes

- Excellent for OEMs: Compact size facilitates integration into tight machine spaces and speeds up installation

- Optional Local Operator Interface (LOI) provides a complete solution for local indication, set point control, and device configuration, eliminating the need for remote secondary electronics

- Variety of communication options available for easy alignment with user requirements

Applications:

- Heat treating, cutting/welding, and other thermal processes

- Solar/thin film physical vapor deposition (PVD) systems

- Analytical devices for measuring and controlling reagent, calibration, and sample gas flows