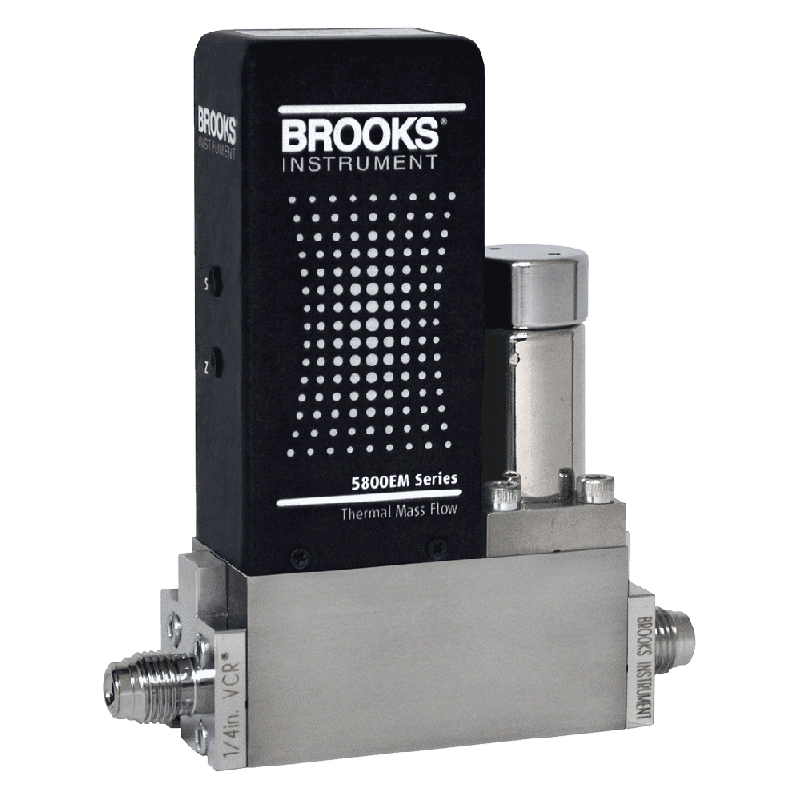

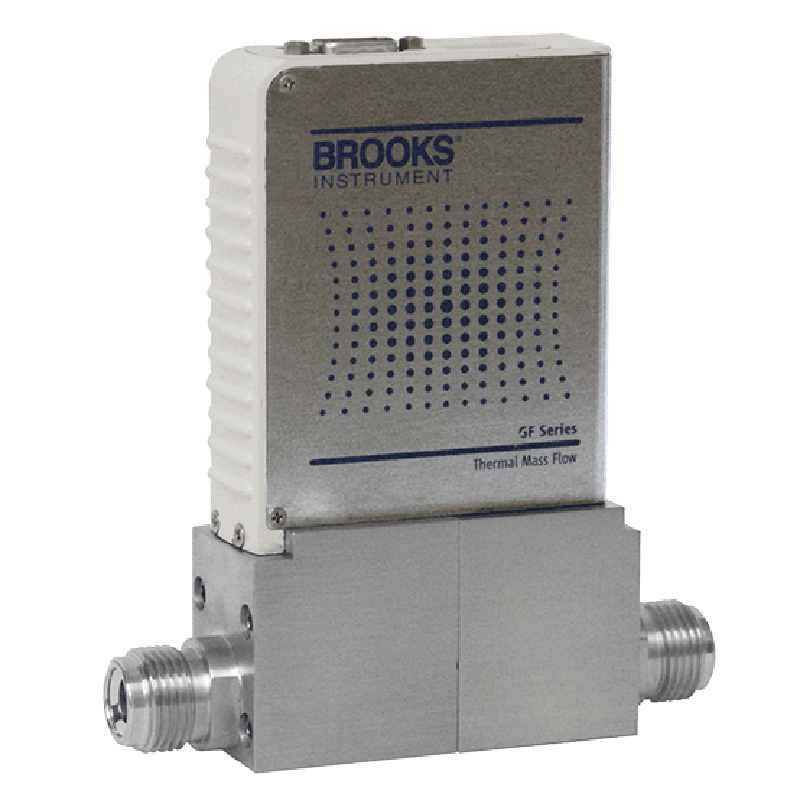

BROOKS 5850EM Series Metal Sealed Thermal Mass Flow Controllers

Proven long-term stability. Ultra-pure performance for high pressure applications.

Description

Proven long-term stability. Ultra-pure performance for high pressure applications.

Models 5850EM / 5851EM

| Performance | |

| Repeatability | 0.2% of rate |

| Response Time | Normally Ciosed Valve: <3 secOptional: 600 msec |

| Flow Range (Full Scale Capacity) | 3 socm -30,000 sccm |

| Linearity | ±0.5% FS.(included in accuracy) |

| Accuracy | 19 F.s. incl. linearity 1.5%6 FS. incl: linearity >20 slpm |

| Multi-Gas & Range Configurability | – |

| Pressure Transient Insensitivity | – |

| Control Range | 2.3%-100% |

| Number of Bins | N/A |

| Valve Shut Down | N/A |

| Zero Stablllty | <±0.5% F.5. per year |

| Mechanical | |

| Wetted Materials | Valve Seat: 316L, Vitons fluoroelastomers, Buna-N, Kalrez® or Teflon® |

| Seal Material | Metal |

| Level of Purity/ Surface Finish | 316L VAR, 316L, and high alloy ferritic stainless steel |

| Valve Options | Normally Closed, Normally Open Meter (no valve) |

| Electrical | |

| Analog communication |

4-20 mA

0-5 Vdc

|

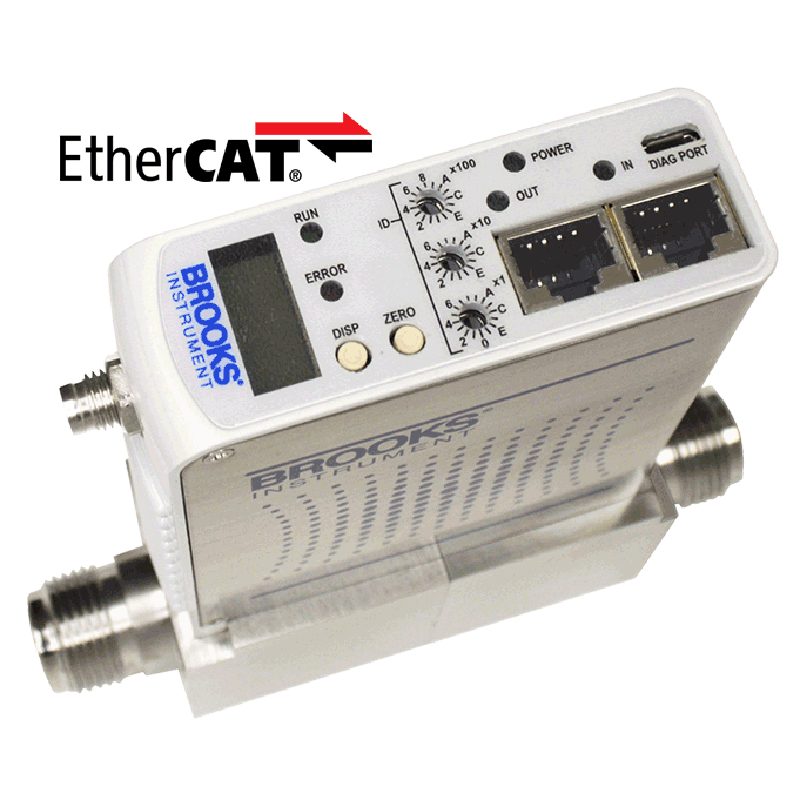

| Digital Communication | – |

| Electrical Connection |

15 Pin D Connector(DA-15P) |

| Power Supply/Consumption |

Normally Closed valve: 3.25 watts

Normally Open valve: 10.5 watts

|

| Ratings | |

| Max Temperature | 65°C |

| Max Pressure | 1500 psi |

| PDifferential Pressure Range |

5 -50 psi (gas and range dependent)

|

| Leak Integrity |

1×10-10 atm cc/sec He

|

| Diagnostics & Display | |

| Diagnostic Capability | – |

| Status Lights |

MFC Health, Network Status |

| Alarms | Control Valve Output, Network Interruption |

| Diagnostic/Service Port | N/A |

| Compliance | |

| EMC | (89/336/EEC) per 61326 |

| Environmental Compliance | N/A |

Features:

- Long-term zero stability of less than 0.2% full scale per year

- Settling time of less than 3 seconds with negligible overshoot/undershoot when commanding changes

- Wide flow range from 3 sccm up to 30,000 slpm

- High pressure rating of up to 1,500 psi

- Optional enhanced internal process finish with a 5µ inch Ra average

- Removable flow sensor

- Insensitive to mounting attitude

- Mechanical and electrical compatibility with other mass flow controllers

- TTL compatible “valve off” and purge function

Benefits:

- All-metal flow path enhances gas purity and reduces leaks

- Proven long-term stability and accuracy across a broad range of processes and applications

- Excellent return on investment due to reliable performance

- Removable flow sensor eliminates the need for continuous monitoring and readjustment of gas pressures

- Easy installation and servicing with analog-only inputs/outputs

Applications:

- Fiber Optic

- LED/MOCVD

- Semiconductor

- Solar