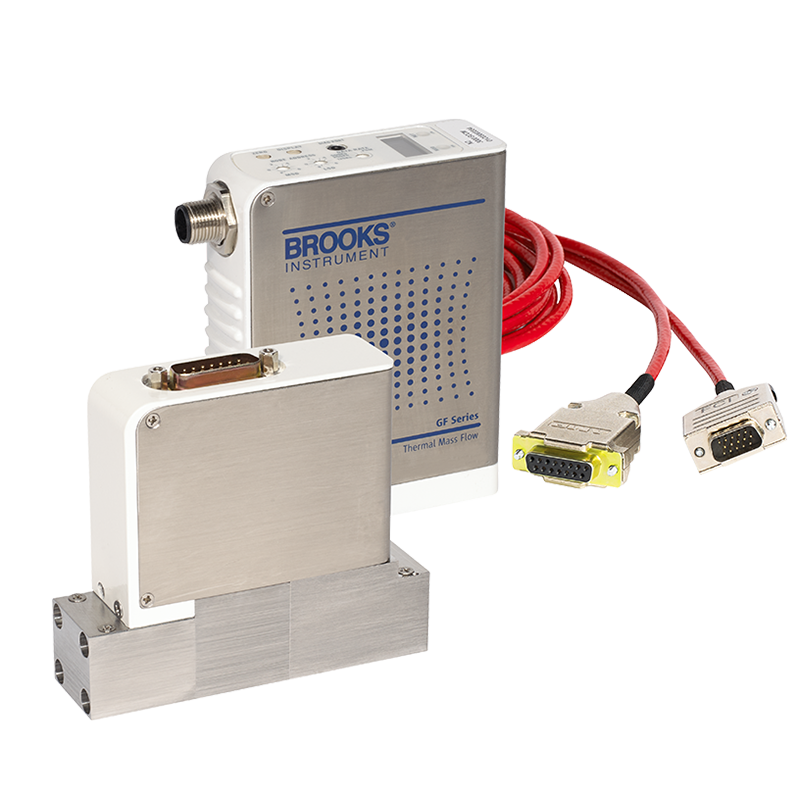

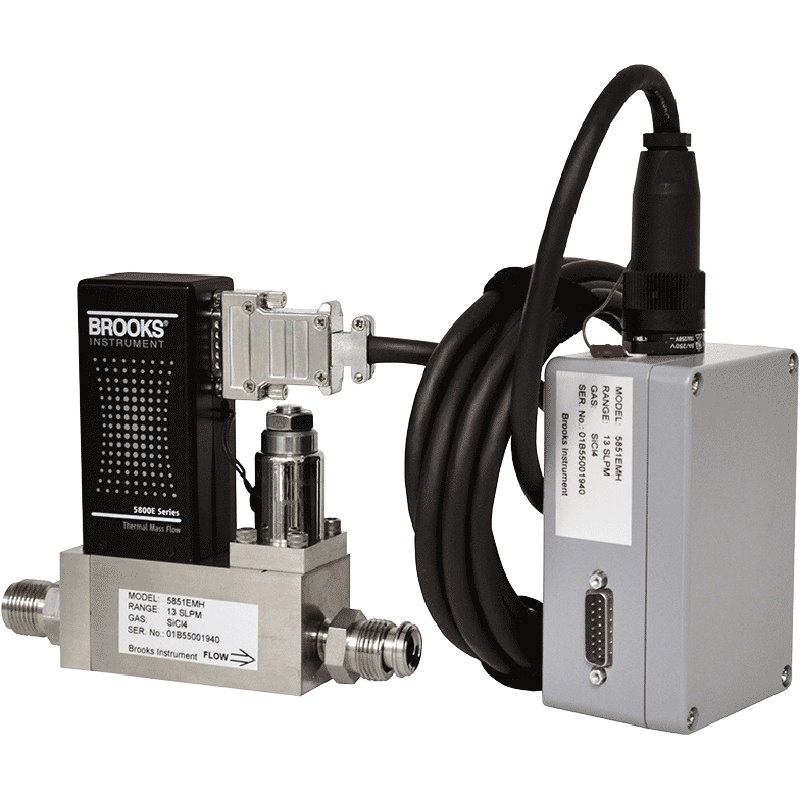

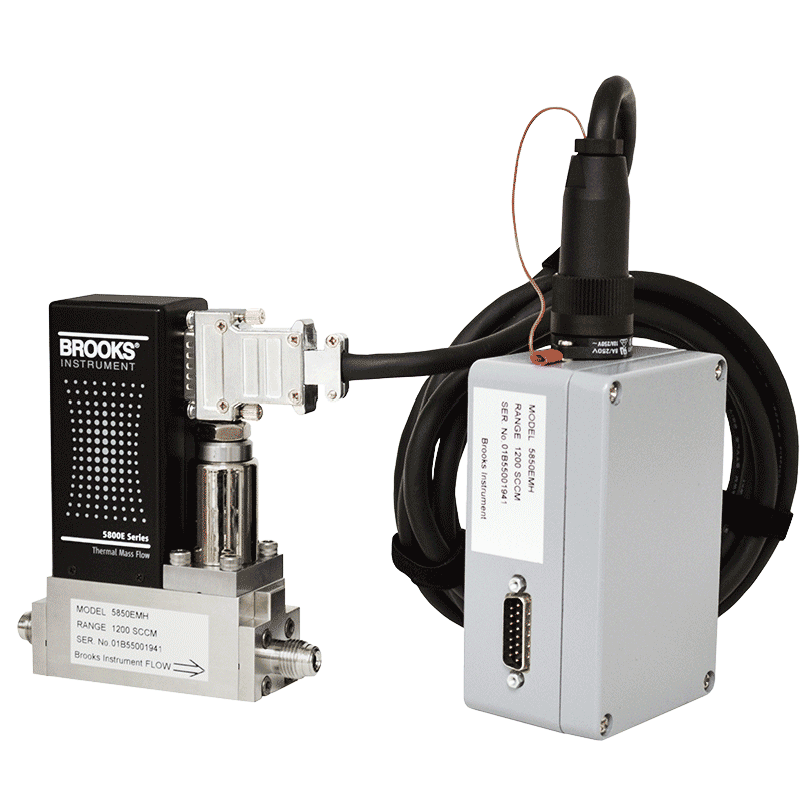

BROOKS GF80 Series Metal Sealed Thermal Mass Flow Controllers & Meters

Raises the standard in performance for value-driven metal sealed applications.

Description

GF80 Series Metal Sealed Thermal Mass Flow Controllers & Meters

Raises the standard in performance for value-driven metal sealed applications.

| Performance | |

| Repeatability | <±0.2% S.P |

| Response Time | Normally Closed Valve: <1 sec |

| Flow Range (Full Scale Capacity) | 3 sccm – 55 slm |

| Linearity | +0.5% FS.(included in accuracy) |

| Accuracy |

+1% S.P. 35-100%

+0.35% F.S.<5-35%

|

| Multi-Gas & Range Configurability | MultiFlo tm Available |

| Pressure Transient Insensitivity | – |

| Control Range | <5%-100% |

| Number of Bins |

Standard GF Series: 11 bins

High Flow GF Series: 4 bins

|

| Valve Shut Down |

Standard GF Series: < 1% F.S.

Hiah Flow GF Series: < 4% of Standard Confiquration F.S. @ 30psig/atm out N2 equiv.

|

| Zero Stability |

<+0.5% F.S. per year

|

| Mechanical | |

| Wetted Materials |

316 Stainless Steel

Hastelloy C-22

17-7 PH

430SS

KM-45

|

| Seal Material | Metal |

| Level of Purity/ Surface Finish | 16μ inch Ra |

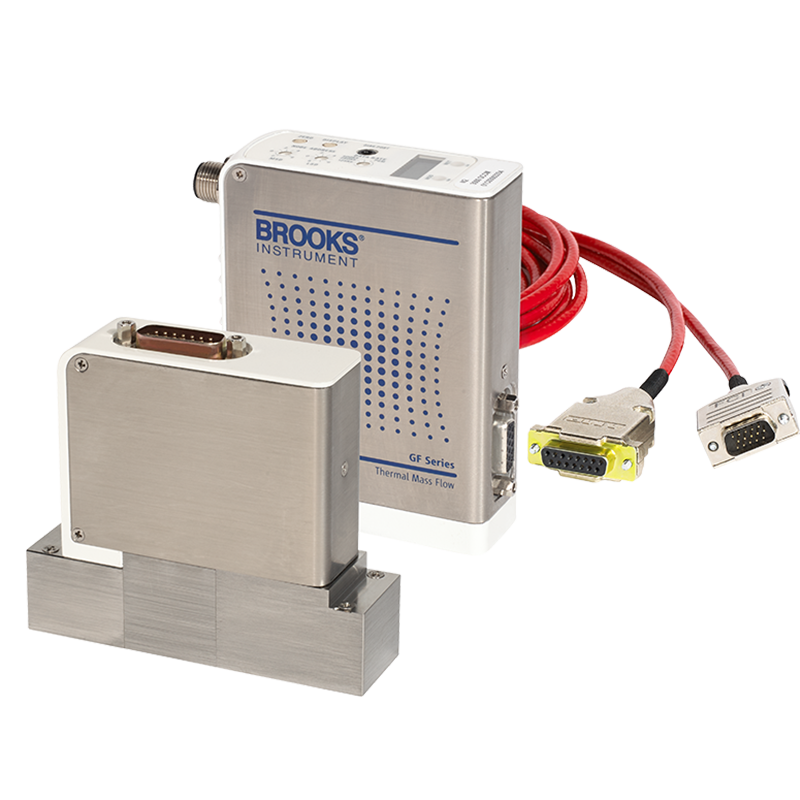

| Valve Options |

Normally Closed

Meter (no valve)

|

| Electrical | |

| Analog communication |

0-20 mA

4-20 mA

0-5 Vdc

0-10 Vdc

|

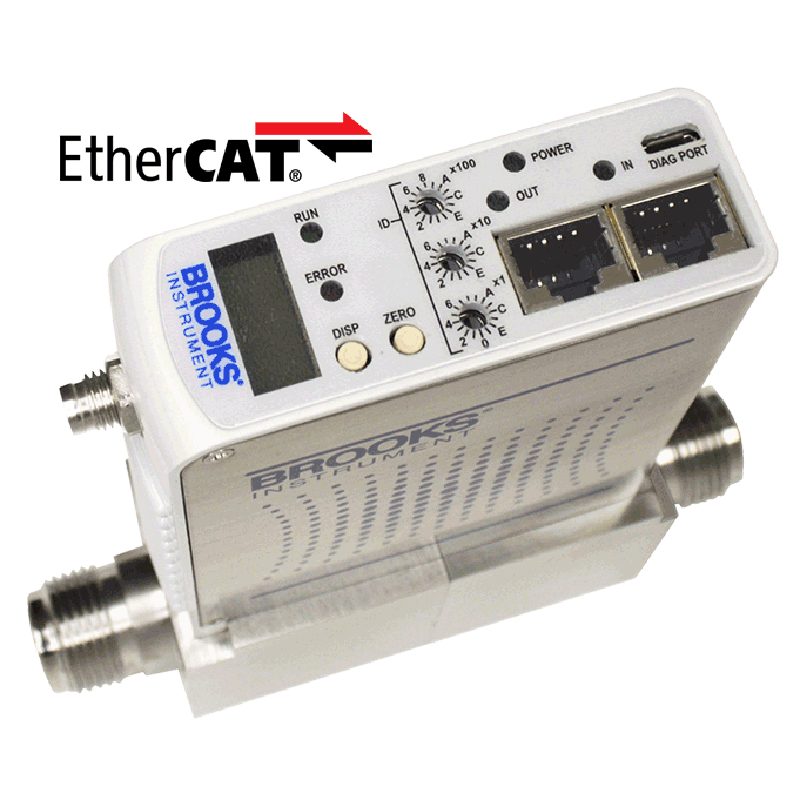

| Digital Communication |

DeviceNetTm

Profibus®

RS485 S-Protocol

RS485 L-Protocol

|

| Electrical Connection |

Profibus/Analog via 9-Pin “D” connector

RS485/Analog via 9-Pin”D” connector, 15-Pin “D” connector

DeviceNetrm via 5-Pin “M12” connector

|

| Power Supply/Consumption |

Standard GF Series: RS485 from +12 Vdc to +24 Vdc=7 Watts max

Profibus from +13.5 Vdc to +27 Vdc =7 Watts max

DeviceNettm from +11 Vdc to +25 Vdc =13.6 Watts max

High Flow GF Series: RS485 from +12 Vdc to +24 Vdc = 3.3 Watts max

Profibus from +13.5 Vdc to +27 Vdc =3.3 Watts max

|

| Ratings | |

| Max Temperature | 50°C |

| Max Pressure |

Standard GF Series: 150 psig (10 bar)

High Flow GF Series: Meter= 75 psig (5 bar), Controller = 150 psig (10 bar)

|

| Differential Pressure Range |

3-860 sccm=7-45 psid

861-7200 sccm=15-45 psid

7201-50000 sccm=25-45 psid

51-300 slm=30-90 psid

(typical pressure drops)

|

| Leak Integrity |

1×10-10 atm cc/sec He

|

| Compliance | |

| EMC | CE: EN6126: 2006 (FCC Part 15 & Canada lC-subset of CE testing) |

| Environmental Compliance |

Safety EN61010-1

RoHS

|