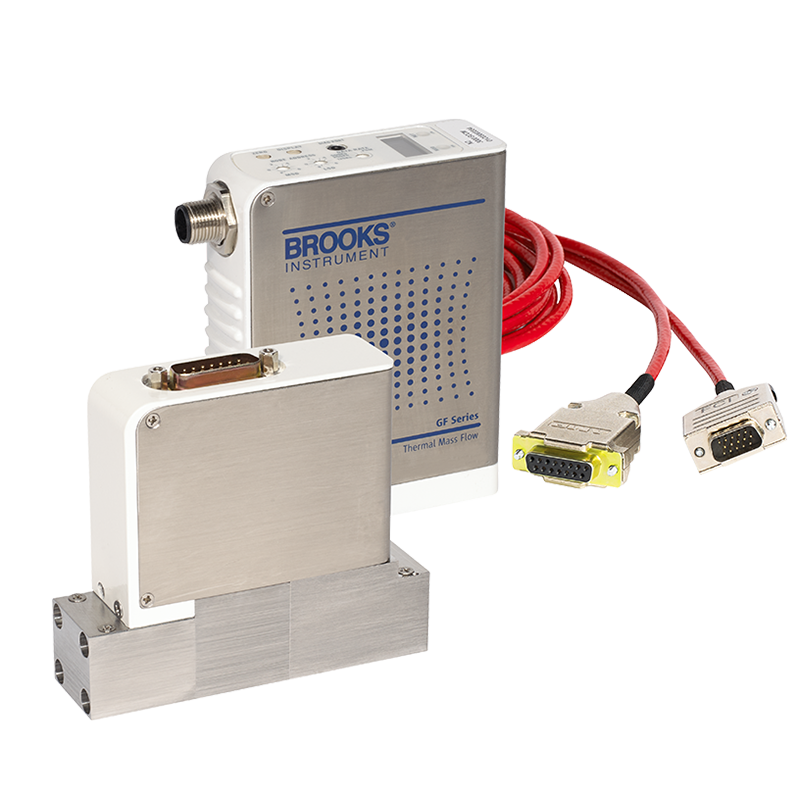

BROOKS GP200 Series Metal Sealed Pressure-based Mass Flow Controllers

All of the performance. None of the limitations.

Description

All of the performance. None of the limitations.

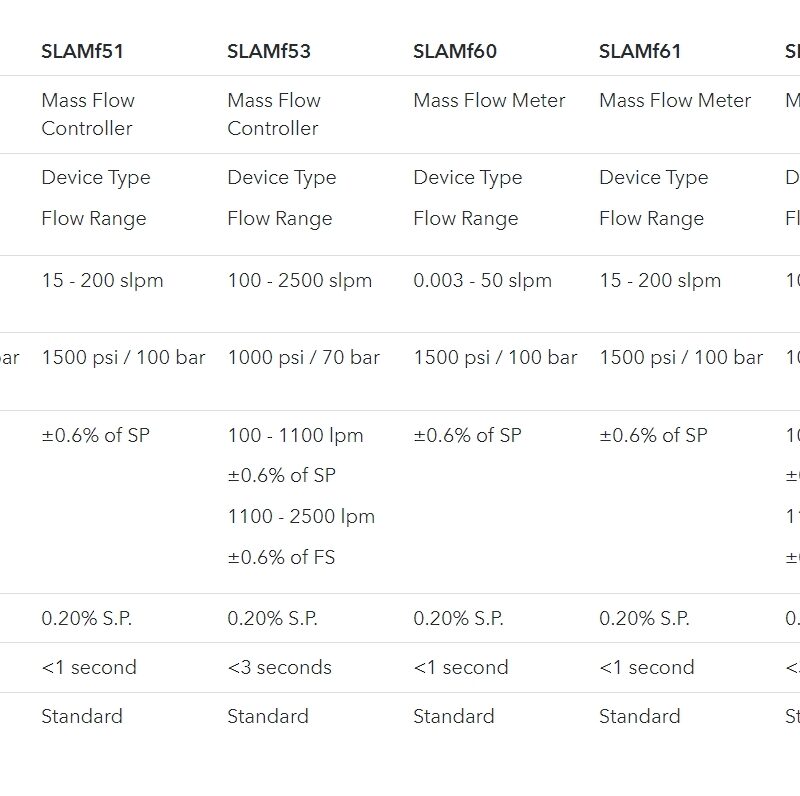

| Performance | |

| Repeatability | <±0.15% S.P. |

| Response Time | 280 + 20 ms Matched Transient Response, for any ascending or descending non-zero setpoint |

| Flow Range (Full Scale Capacity) | 3 sccm – 50,000 sccm |

| Accuracy |

Zero Leak Valve

<+1% S.P. (5-100% F.S.)

<+0.05% F. S.(0.5-5% F.S.)

Metal Seal Valve

<+1% S.P. (5-100% F.S.)

<+0.05% F S.(2-5% F.S.

|

| Multi-Gas & Range Configurability | MultiFlo tm Standard |

| Pressure Transient Insensitivity | <+ 1% S.P, up to 40 psi/secinlet pressure spike |

| Control Range |

Zero Leak Valve

0.5 – 100% F.S.

Metal Seal Valve

2-100% F.S.

|

| Number of Bins |

Nine (9) standard bin ranges

|

| Flow Temperature Coefficient |

Zero:0.005% FS.per°C

Span: 0.05% S.P. per°C

|

| Zero Stability |

<+0.15% F.S. per year

|

| Mechanical | |

| Wetted Materials |

316L

Hastelloy C-22

316/316L Stainless Steel304 Stainless Steel

KM-45

PCTFE

|

| Seal Material | Metal |

| Level of Purity/ Surface Finish | 5μ inch Ra avg |

| Valve Options |

Normally Closed

|

| Electrical | |

| Analog communication |

0-5 Vdc

|

| Digital Communication |

DeviceNetTm

EtherCAT®

RS-485 L-Protocol

|

| Electrical Connection |

Analog/RS-485 via 9-Pin “D” connector

DeviceNetrm via 5-Pin “M12” connector

EtherCATo via RJ45 jacks, Power via 5-pin M8 connector

|

| Power Supply/Consumption |

Analog/RS-485 L Protocol: 6 Watts max @ +15 Vdc (+10%) or +24 Vdc(+10%)

DeviceNetrm:545 mA max @ +11-25 Vdc, 250 mA max @ 24 VdcEtherCATTm:360 mA max @+18-30 Vdc, 270 mA max @ 24 Vdc(Under typical operating conditions)

|

| Diagnostics & Display | |

| Diagnostic Capability |

DeviceNet

MFC Health

Network Status

EtherCAT

Run

Error

Power

Network Status

RS-485 (analog)

Network Status

|

| Alarms |

Process Control Deviations

Flow

Temperature

*For full list of alarms see supplemental communication manuals

|

| Diagnostic/Service Port | RS-485 via micro-USB |

| Display |

Top Mount integrated LCD

Viewing Angle: Rotatable

Viewing Distance: 10 feet

Units Displayed: Flow (%), Temp (°C), Pressure (psia, kPa)

Resolution: 0.1 (unit)

|

| Ratings | |

| Max Temperature | 60°C |

| Max Pressure |

150 psia

|

| Differential Pressure Range |

Min: 7 psid

Max: up to 50 psid

|

| Compliance | |

| EMC | 2014/30/EU EMC Directive EN:61326-1:2013 |

| Environmental Compliance |

2011/65/EU&2015/863/EU RoHS Directive

EC 1907/2006 REACH Directive

|

Features:

- True differential pressure measurement

- Lower inlet pressure operation capability

- Downstream valve architecture

- Matched transient response

- Zero Leak-by Control Valve

- MultiFloTM technology allows for flexible programming of gas and flow range configurations without removing the MFC from the gas line or compromising accuracy

- Local display indicates flow, temperature, pressure, and network address

- DeviceNetTM, EtherCAT®, RS-485 L-Protocol, and analog interfaces

Benefits:

- GP200 differential pressure technology reduces measurement uncertainty, enhancing accuracy, repeatability, and drift performance by eliminating the need to match and compensate two separate pressure transducers.

- Safer operation at lower inlet pressures possible with a P-MFC using the optimized GP200 differential pressure sensor for low differential pressure measurement.

- Accuracy remains independent of downstream pressure due to the downstream valve architecture, enabling flow delivery into pressures as high as 1200 Torr. The fast closing valve addresses non-productive recipe wait times and mitigates “tail effects” seen in upstream MFC valve designs that require additional time to bleed down their internal gas volume.

- Ultra-fast and highly repeatable ascending and descending flow stabilization time allows for tighter process control in advanced high-cycle Deposition and Etch processes.

- 100X improvement in valve shut-down capability.

- MultiFloTM enables re-scaling of MFC full-scale flow range down by a factor of 3:1 without impacting accuracy, turndown, or leak-by specifications, providing process and inventory flexibility.

- Convenient user display and independent diagnostic/service port facilitate device installation, monitoring, and troubleshooting.

Key Applications:

- Semiconductor manufacturing

- Etch processes

- Chemical Vapor Deposition (CVD)

- Gas flow control applications that require a high-purity all-metal flow path