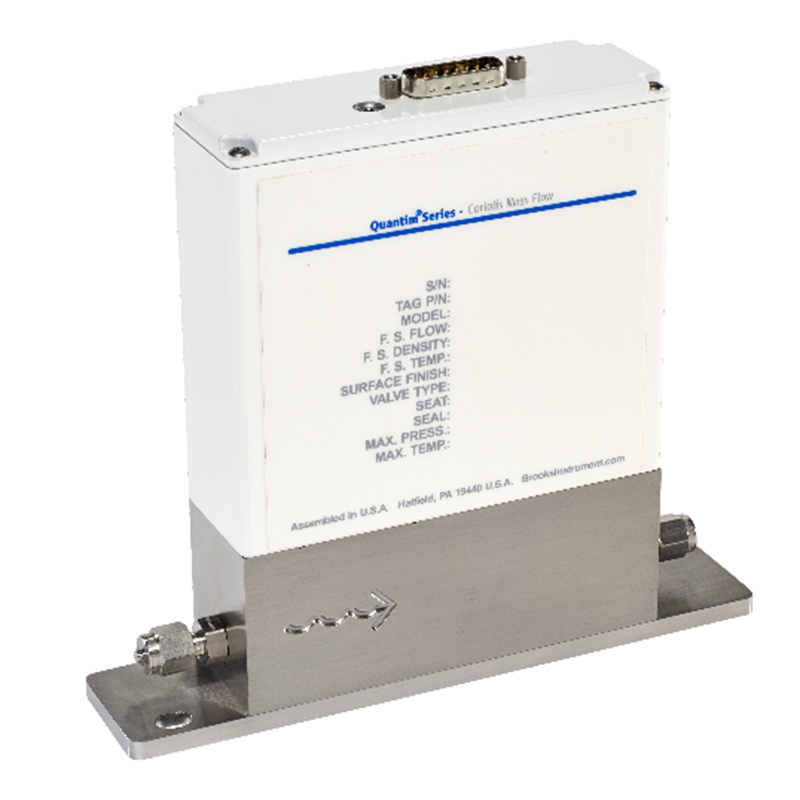

BROOKS Quantim QMC Coriolis Mass Flow Meters & Controllers

Third generation Coriolis sensor and electronics provides superior performance and reliability

Description

New third-generation Quantim QMC Coriolis flow meters are ideal for very low-flow gas and liquid measurement and control applications.

Models QMC / QMB

Features:

- True mass flow measurement

- Accurate density measurement

- NEW I/Os: 0-10 Vdc, 0-20 mA, RS485 S-Protocol

- Variety of material options, enclosure types, and area classifications available

- NEW easy-to-access external service port

- NEW Quantim® QMC Coriolis series is form-, fit-, and function-compatible with prior Brooks Instrument Quantim® models

Benefits:

- Process chemistry and conditions can be altered without changing or recalibrating the measurement system

- All-stainless steel construction makes Quantim® QMC compatible with most process fluids

- External service port, accessible via a 2.5 mm jack plug, coupled with Brooks Expert Support Tool (BEST) software, enables on-board alarms and diagnostics for enhanced process monitoring and predictive maintenance

- Simplified installation, troubleshooting, and calibration verification

Applications:

- Catalyst research

- Mass balance calculations in chemical pilot plants

- Liquid precursor delivery to vaporizers

- Precision coatings

- High-accuracy filling stations

- Metering pump feedback/control loop

- Vacuum processes

- Semiconductor wafer processing

| Performance | |

| Repeatability | ±0.0596 or ±[0.5 x (zero stability/flowrate) x 100]% of rate whichever is greater |

| Response Time | SS Controller: <2 sec S5 Meter: <0.5 sec |

| Flow Range (Full Scale Capacity) | 10-27,000 gramvhr |

| Temperature Accuracy | ±0.5°C |

| Accuracy | Standard flow Accuracy (below) or [(zero stabllty/flow rate) x 1001%6 of rate, whichever is areater Liguid: 0.2% of rate Gas: 0.5%6 of rate |

| Differential Pressure Range | Liquid: 10-200 psi Gas: 10 . 150 psi |

| Density Range | 0 to 2.0 g/cc |

| Density Accuracy | +0.005 g/cc |

| Leak integrity | Flastomer Seal: Outboard 1 x 10-9 atm,cc/sec, helium (max) Metal Seal: 1 x10-10 atm.cc/sec, helium (max) |

| Mechanical | |

| Wetted Materials | 316L, 316LVAR, High Alloy Ferritic Stainless & 17-7PH |

| Seal Material | Viton, Buna, Kalrez, EPDM or Metal |

| Housing | Standard: IP40 |

| inlet Filter | Size 2 Sensor: 1 & 10 micron Slze 3 & 4 Sensors: 10,20, 30 & 40 micron |

| Fittings |

Elastomer Seal: 1/16″, 1/8~, 1/4″ or 6mm tube compression

1/8 or 1/4” NPT(F)

1/8*or 1/4*VCR, 1/4″VCO

Metal Seal: 1/8″ or 1/4″ VCR, 3.2mm UPG

See Model Code

|

| Electrical Connection | IP40: 15 pin D-Type connector |

| Electrical | |

| Analog communication | 0.5 Vde 0.10 Vdc 0-20 mA 4-20 mA |

| Digital Communication | RS-485(Smart Protocol) |

| Ratings | |

| Max Temperature | 0-65°C |

| Max Pressure | Standard internal Valve: 500 psig Optional internal Valve: 1500 psig |

| Power Supply/Consumption |

Voltage: +14-27 Vdc

Nominal Current: 300-300 mA(contraller): 100-150 mA(meter)

Maximum Current: 715 mA @ 14 Vdc (controiler); 470 mA @ 14 Vdc (meter)

Maximum Power: 10.0 W(controller0, 6.6 W(meter)

|

| Diagnostics | |

| Diagnostic Capability | LED Status light Open Collector Alarm Output Advanced diagnostics, alarms & warnings available via digital l/O |

Learn more about the importance of adding filtration and other tips to prevent clogging in low-flow applications using Coriolis mass flow controllers from this article in Chemical Engineering, authored by Brooks Instrument.