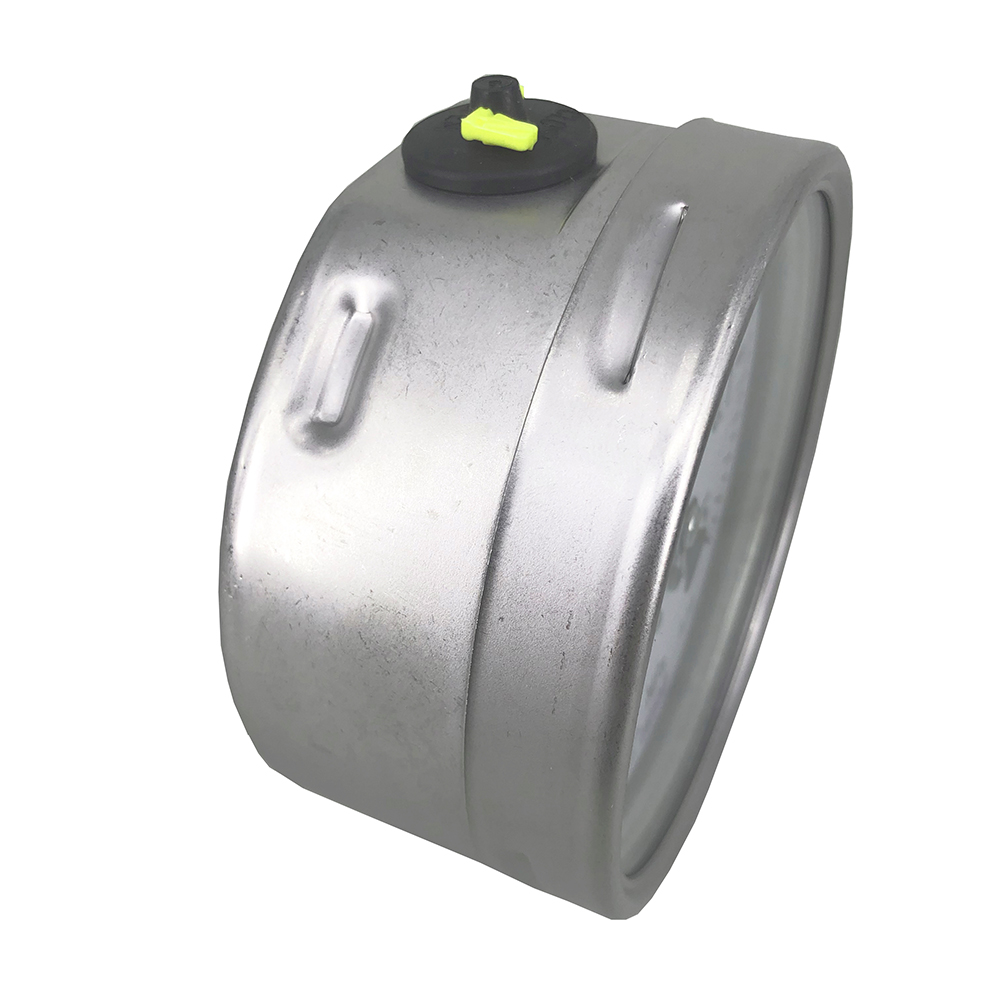

Wika 233.50 Bourdon Tube Pressure Gauge Stainless Steel

The model 233.50 with liquid-filled case is suitable for highdynamic pressure loads and vibrations.

Description

This high-quality Bourdon tube pressure gauge has beendesigned especially for the process industry.

The use of high-guality stainless steel materials and therobust design are geared to applications in the chemicaland process engineering industries.Thus the instrument issuitable for liquid and gaseous media, also in aggressiveenvironments.

Scale ranges of 0 … 0.6 to 0 … 1,600 bar [0 … 10 to0 …20.000 psil ensure the measuring ranges required for awide variety of applications.

WlKA manufactures and qualifies the pressure gaugcin accordance with the standards EN 837-1 andASME B40,100.As a safety function, this instrument has ablow-out device with blow-out plug on the back of the case. Inthe event of a failure,overpressure can escape there.

The model 233.50 with liquid-filled case is suitable for highdynamic pressure loads and vibrations.

The QR code on the dial allows instrument-specific informa.tion such as the serial number, the order number. certificatesand other product data to be retrieved from the internet easilyand in the long term.

Specifications

| Basic information | |

| Standard |

EN 837-1

ASME B40.100

|

| For information on the”Selection, installation, handling and operation of pressuregauges”,see technical information lN 00.05. | |

| Further version |

Oil- and grease-free for oxygen

Per NACE MR0175 /1$0 15156, use in H,S-containing emvironments in oiland gas production

With pre-volume deflagration flame arrester for mounting to zone 0 (EPL Ga); model 910,21; see data sheet AC 91.02

Monel version; models 262 and 263; see data sheet PM 02.33

|

| Nominal size(NS) |

Φ63 mm [2 ½”]

Φ100 mm [4″]

Φ160 mm [6″]

|

| Connection location |

Lower mount (radial)

Lower back mount

Centre back mount (only for NS 63 [2 ½”])

|

| Window |

Laminated safety glass (NS 63 [2 “]: Polycarbonate)

|

| Case | |

| Design |

Safety level”S1″ per EN 837-1

With blow-out device at case circumference, 12 o’clock (NS 63 [2 ½”]) and on theback of the case (NS 100 [4″] and 160 [6″])

Scale ranges ≤ 0 . 16 bar [≤ 0 …300 psi] with compensating valve to vent andresealcase

|

| Material |

Stainless steel1.4301(304)

Stainless steel 1.4571(316Ti)

|

| Ring |

Bayonet ring, stainless steel

|

| Mounting |

Without

Panel mounting flange, stainless steel

Panel mounting flange, polished stainless steel

Triangular profile ring with mounting bracket, polished stainless steel

Surface mounting flange, stainless steel

|

| Case fllllng (model 233.50) |

Without

Glycerine

Glvcerine-water mixture for NS 100 [4″] and 160 [6″] with scale range≤0 …2.5 bar[≤ 0 …40 psi] or for NS 63 [2 “] with scale range ≤ 0 … 4 bar [≤ 0..60 psi]

Silicone oil

|

| Movement |

Stainless steel

Stainless steel1.4404 (316L)

everlast® version

|

| Measuring element | ||

| Type of measuring element |

Bourdon tube, C-type or helical type

|

|

| Material |

Stainless steel 1.4404 (316L)

|

|

| Leak tightness |

Helium tested, leakage rate:< 5.10-3 mbar l/s

Helium tested, leakage rate:< 1.10s mbar l/s

|

|

| Accuracy specifications | ||

| Accuracy class | ||

| NS 63 [2 ½”] | EN 837-1 | Class 1.6 |

| ASME B40.100 | ±2 % | ±1% | +2 % of measuring span (grade A) | |

| NS 100 [4″], 160 [6″] | EN 837-1 | Class 1.0 |

| ASME B40.100 | +1%of measuring span (grade 1A) | |

| Temperature error | On deviation from the reference conditions at the measuring system.≤ ±0.4 % per 10 “C [≤ ±0,4 % per 18 °F] of full scale value | |

| Reference conditions | ||

| Ambient temperature | +20 °C [68 °F] | |