YOKOGAWA ROTAMASS Hygienic Coriolis Mass Flow Meters

With Pure Dedication

Meticulously engineered and certified for utility applications in the food & beverage, biotechnology, and pharmaceutical industries. (Certified by EHEDG and 3-A)

This series offers the perfect solution to address the daily challenges faced in hygienic processes, ensuring consistent product quality while minimizing losses. The multi-variable measurement capability and a range of dedicated features make it effortless to achieve these goals.

With Pure Dedication

Meticulously engineered and certified for utility applications in the food & beverage, biotechnology, and pharmaceutical industries. (Certified by EHEDG and 3-A)

This series offers the perfect solution to address the daily challenges faced in hygienic processes, ensuring consistent product quality while minimizing losses. The multi-variable measurement capability and a range of dedicated features make it effortless to achieve these goals.

Typical Applications

Specification & Function

Refer to the General Specification sheet located under the ‘Downloads’ tab for detailed specifications.

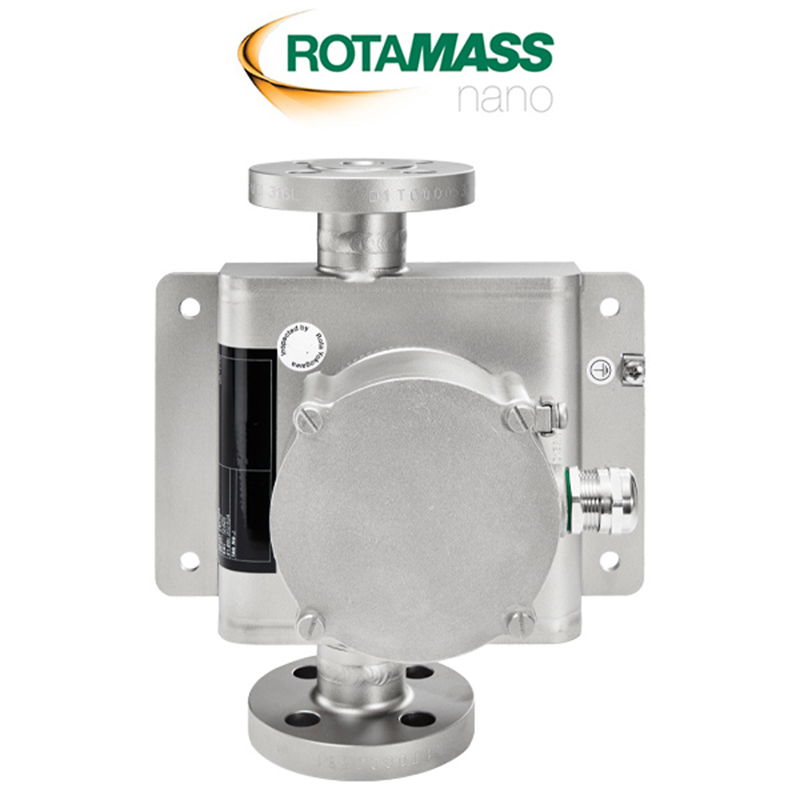

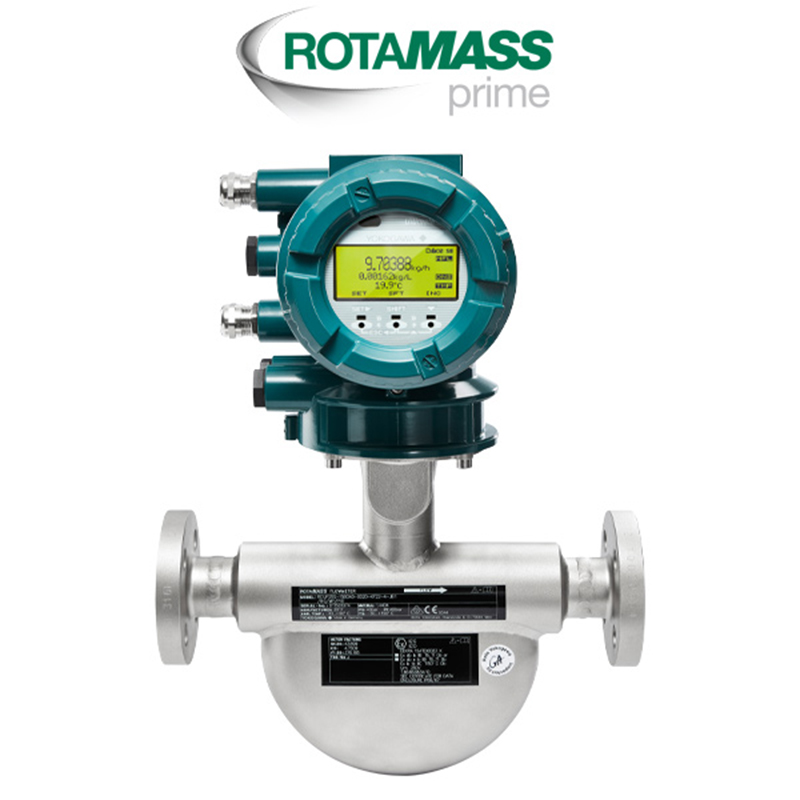

| Product Line | Rotamass Nano | Rotamass Prime | Rotamass Hygienic | Rotamass Supreme | Rotamass Intense | Rotamass Giga |

| Liquid process fluids | ||||||

| Liquids in general | ● | ● | ● | ● | ● | ● |

| Aggressive liquids | ○ | – | – | ● | ● | ○ |

| High viscous fluids | ○ | ● | ● | ○ | ○ | ○ |

| Gaseous process fluids | ||||||

| Gases in general | ○ | ● | ○ | ○ | ○ | ● |

| Low density gases | ○ | ● | ● | ○ | ○ | ○ |

| Mixed process fluids | ||||||

| Unmixable or mixable liquids | ● | ● | ● | ● | ● | ● |

| Liquids with entrained gas | ● | ● | ● | ● | ● | ○ |

| Process conditions | ||||||

| Process temperature | -50 to +260 °C -58 to +500 °F |

-70 to +200 °C -94 to +392 °F |

-70 to +140 °C -94 to +284 °F |

-196 to +350 °C -321 to +662 °F |

-70 to +150 °C -94 to +302 °F |

-70 to +350 C or +200 C (Giga 2F) -94 to +662 F or +392 F (Giga 2F) |

| Process pressure up to | 285 bar or 460 bar *1 4183 psi or 6672 psi *1 |

100 bar 1450 psi |

40 bar 580 psi |

100 bar or 250 bar *1 1450 psi or 3626 psi *1 |

up to 700 bar 10000 psi |

100 bar or 180 bar *1 1450 psi or 2610 psi *1 |

| Line sizes | DN15 to DN40 1/4 in. to 1 1/2 in. |

DN15 to DN125 3/8 in. to 5 in. |

DN25 to DN80 1 in. to 3 in. |

DN15 to DN125 3/8 in. to 5 in. |

9/16 or 3/4“in. AutoClave 1/4 in. to 2 in. |

DN100 to DN250 4 in. to 10 in. |

| Accuracy | ||||||

| Mass flow for liquids up to | ± 0.1 % | ± 0.1 % | ± 0.1 % | ± 0.1 % | ± 0.1 % | ± 0.1 % |

| Mass flow for gas up to | ± 0.50 % | ± 0.35 % | ± 0.35 % | ± 0.35 % | ± 0.50 % | ± 0.35 % |

| Density for liquids up to | ± 0.5 g/l | ± 0.5 g/l | ± 0.5 g/l | ± 0.5 g/l | ± 0.5 g/l | ± 2.0 g/l |

| Turndown flat accuracy | ○ | ● | ● | ○ | ○ | – |

| Materials and process connections | ||||||

| Material of wetted parts | Alloy C-22/2.4602 & 316L/1.4404 | 316L/1.4404 | 316L/1.4404 | 316L/1.4404 or alloy C-22/2.4602 or 304/1.4301 *1 | 316L/1.4404 or alloy C-22/2.4602 or 304/1.4301*1 | 316L/1.4404 or alloy C-22/2.4602 (Giga 1F only) |

| Flange process connections | EN, ASME, JPI, JIS | EN, ASME, JPI, JIS | − | EN, ASME, JPI, JIS | ASME | EN, ASME, JIS |

| Threaded process connections | G, NPT | G, NPT | DIN11851, SMS1145 | G, NPT | G, NPT | − |

| Clamp process connections | DIN32676 | − | DIN32676, JIS/ISO2852 | DIN32676, JIS/ISO2852 | − | − |

| Sensor design | ||||||

| Insulation and heat tracing options | ● | – | – | ● | – | ● |

| Rupture disk | ○ *1 | – | – | ● | ● | ● |

| Customer & NAMUR face-to-face length | ● | ● | – | ● | – | ○ |

| Approvals / Certificates | ||||||

| 3-A, EHEDG, EC1935:04 and EC2023:06 | – | – | ● | ● | – | – |

| Marine application | ● | ● | ● | ● | ● | ○ |

| Functional Safety | SIL 2 (SIL3) | |||||

| Custody transfer application | NTEP (Nano 20) | NTEP | NTEP | NTEP, INMETRO | NTEP | NTEP, INMETRO |

| Hazardous area approvals | IECEx, ATEX, UKEx, FM (USA/Canada), NEPSI, INMETRO, PESO, EAC Ex, Taiwan Safety Label, Korea Ex, Japan Ex, ECAS Ex, Ukraine Ex | |||||

●: supported ○: supported under certain conditions -: not supported *1: available on demand