Safe Under High Pressure

The Coriolis Mass Flow and Density Meters are engineered with an exceptionally robust and durable design, ensuring accurate measurement in high-pressure environments.

Safety is of paramount importance, particularly in high-pressure operations. That’s why this series has been meticulously designed to meet the most stringent safety standards. Additionally, with advanced diagnostics like the Total Health Check function, operators can maintain secure control over operations at all times.

Typical Applications

Specification & Function

Refer to the General Specification sheet located under the ‘Downloads’ tab for detailed specifications.

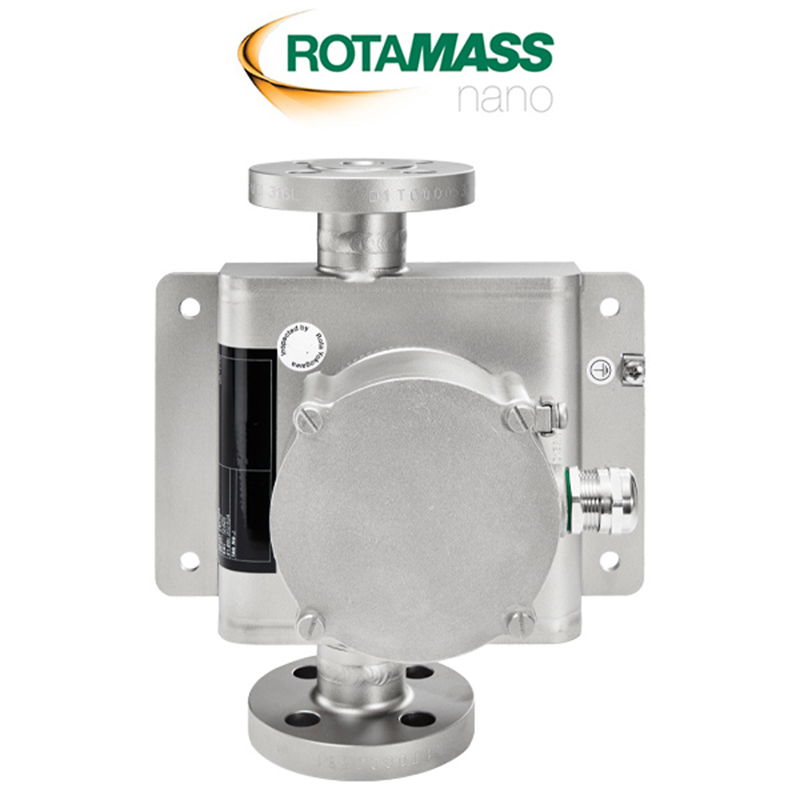

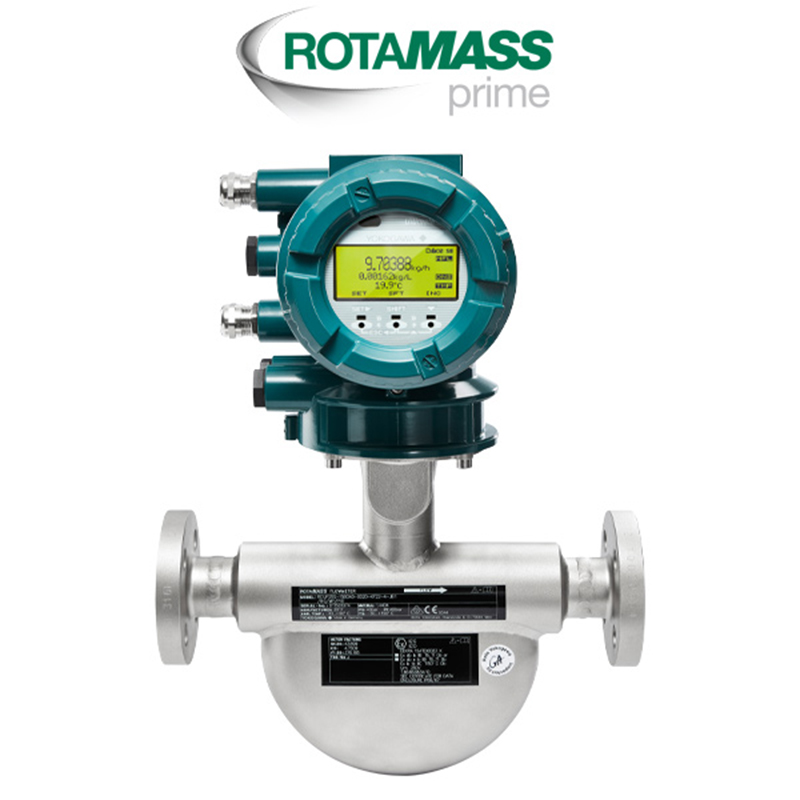

| Product Line | Rotamass Nano | Rotamass Prime | Rotamass Hygienic | Rotamass Supreme | Rotamass Intense | Rotamass Giga |

| Liquid process fluids | ||||||

| Liquids in general | ● | ● | ● | ● | ● | ● |

| Aggressive liquids | ○ | – | – | ● | ● | ○ |

| High viscous fluids | ○ | ● | ● | ○ | ○ | ○ |

| Gaseous process fluids | ||||||

| Gases in general | ○ | ● | ○ | ○ | ○ | ● |

| Low density gases | ○ | ● | ● | ○ | ○ | ○ |

| Mixed process fluids | ||||||

| Unmixable or mixable liquids | ● | ● | ● | ● | ● | ● |

| Liquids with entrained gas | ● | ● | ● | ● | ● | ○ |

| Process conditions | ||||||

| Process temperature | -50 to +260 °C -58 to +500 °F |

-70 to +200 °C -94 to +392 °F |

-70 to +140 °C -94 to +284 °F |

-196 to +350 °C -321 to +662 °F |

-70 to +150 °C -94 to +302 °F |

-70 to +350 C or +200 C (Giga 2F) -94 to +662 F or +392 F (Giga 2F) |

| Process pressure up to | 285 bar or 460 bar *1 4183 psi or 6672 psi *1 |

100 bar 1450 psi |

40 bar 580 psi |

100 bar or 250 bar *1 1450 psi or 3626 psi *1 |

up to 700 bar 10000 psi |

100 bar or 180 bar *1 1450 psi or 2610 psi *1 |

| Line sizes | DN15 to DN40 1/4 in. to 1 1/2 in. |

DN15 to DN125 3/8 in. to 5 in. |

DN25 to DN80 1 in. to 3 in. |

DN15 to DN125 3/8 in. to 5 in. |

9/16 or 3/4“in. AutoClave 1/4 in. to 2 in. |

DN100 to DN250 4 in. to 10 in. |

| Accuracy | ||||||

| Mass flow for liquids up to | ± 0.1 % | ± 0.1 % | ± 0.1 % | ± 0.1 % | ± 0.1 % | ± 0.1 % |

| Mass flow for gas up to | ± 0.50 % | ± 0.35 % | ± 0.35 % | ± 0.35 % | ± 0.50 % | ± 0.35 % |

| Density for liquids up to | ± 0.5 g/l | ± 0.5 g/l | ± 0.5 g/l | ± 0.5 g/l | ± 0.5 g/l | ± 2.0 g/l |

| Turndown flat accuracy | ○ | ● | ● | ○ | ○ | – |

| Materials and process connections | ||||||

| Material of wetted parts | Alloy C-22/2.4602 & 316L/1.4404 | 316L/1.4404 | 316L/1.4404 | 316L/1.4404 or alloy C-22/2.4602 or 304/1.4301 *1 | 316L/1.4404 or alloy C-22/2.4602 or 304/1.4301*1 | 316L/1.4404 or alloy C-22/2.4602 (Giga 1F only) |

| Flange process connections | EN, ASME, JPI, JIS | EN, ASME, JPI, JIS | − | EN, ASME, JPI, JIS | ASME | EN, ASME, JIS |

| Threaded process connections | G, NPT | G, NPT | DIN11851, SMS1145 | G, NPT | G, NPT | − |

| Clamp process connections | DIN32676 | − | DIN32676, JIS/ISO2852 | DIN32676, JIS/ISO2852 | − | − |

| Sensor design | ||||||

| Insulation and heat tracing options | ● | – | – | ● | – | ● |

| Rupture disk | ○ *1 | – | – | ● | ● | ● |

| Customer & NAMUR face-to-face length | ● | ● | – | ● | – | ○ |

| Approvals / Certificates | ||||||

| 3-A, EHEDG, EC1935:04 and EC2023:06 | – | – | ● | ● | – | – |

| Marine application | ● | ● | ● | ● | ● | ○ |

| Functional Safety | SIL 2 (SIL3) | |||||

| Custody transfer application | NTEP (Nano 20) | NTEP | NTEP | NTEP, INMETRO | NTEP | NTEP, INMETRO |

| Hazardous area approvals | IECEx, ATEX, UKEx, FM (USA/Canada), NEPSI, INMETRO, PESO, EAC Ex, Taiwan Safety Label, Korea Ex, Japan Ex, ECAS Ex, Ukraine Ex | |||||

●: supported ○: supported under certain conditions -: not supported *1: available on demand